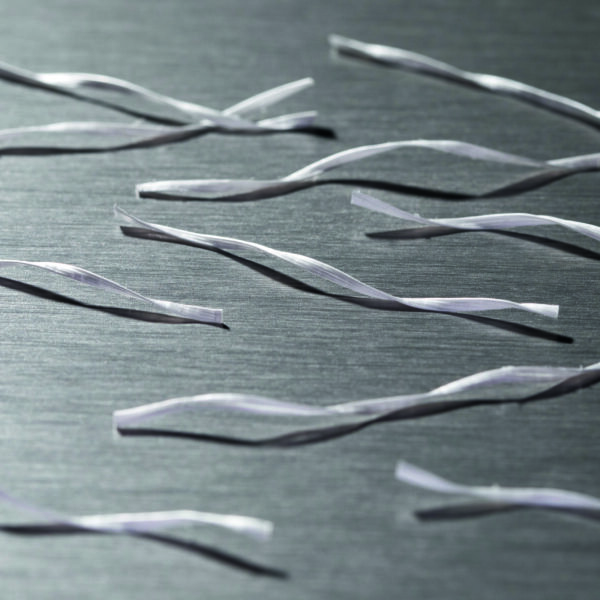

Chryso offers a wide choice of fibres depending on the target applications and performances.

Synthetic fibres help protect fresh concrete from shrinkage cracks (caused by rapid drying of the surface) and thermal cracks (caused by stresses when the concrete heats up during curing and then cools down). Once the concrete has cured, they help hold the cracked sections together.

Natural fibers improve the hydration process of concrete and enhance the color and finish of the surface. Fibers also prevent segregation.

Improved durability

Reduction of cracking

CO2 optimization

Concrete aesthetics

THE ADVANTAGES OF FIBRES

Reduction of micro-cracking

Improved durability

Aesthetic gain

Increased tear resistance

Application of Fibers

Floor covering applications

The CHRYSO® macrofiber range is used as an alternative system to conventional reinforcements such as wire mesh and steel rebar in residential floors, foundations and cover slabs. The use of Chryso macrofibers accelerates project completion while providing superior durability and significant cost savings.

Self leveling screeds microfibres / macrofibres:

Depending on the screed technology used and local regulation, fibres are often used to enhance the robustness (cracking control) of self leveling screeds. Chryso offers high performance fibres designed to preserve the perfect finish and high pumpability required for high flowability screeds.

Chryso fibres are also compatible with heated floors. No disruption, just higher performance.

BENEFITS :

- Perfect finish

- Superior durability

- Savings (time, labor, material)

- Easy to use

Application for underground construction sites

Spalling can be a violent effect on concrete exposed to fire, destroying entire cross-sections or significantly reducing the load-bearing capacity of a construction. The network of large capillaries created by the vaporized fibers allows the internal evacuation of water vapor, thus preventing spalling by fire for several hours.

Chryso offers a complete range of proven fire-resistant fibers and its expertise in the design of suitable coatings, particularly for tunnel segments.

As part of its comprehensive range of tunnel solutions, Chryso’s dedicated macrofibers enable meeting Class A, B and C requirements (EFNARC or ASTM standards). These fibers are designed for easy pumping, maximum bounce reduction and ultimate tensile strength performance.

Combined with the Chryso®Jet range of admixtures and our expertise in concrete mix design, they guarantee a flawless and successful operation throughout the project.

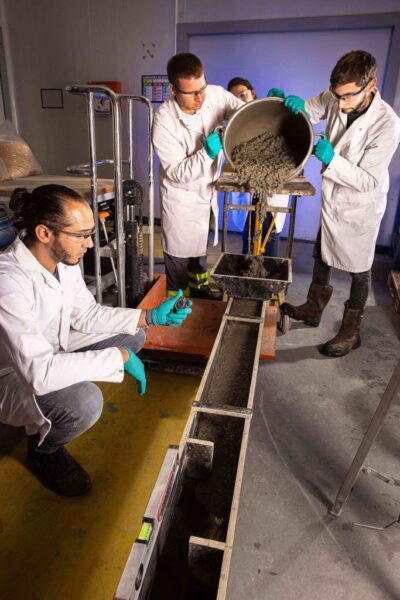

Chryso services to optimize your production

Fibre-reinforced concrete full technical support

Chryso provides a complete service for sizing and optimization of mix design:

- Design of fiber concrete mixes: complete drafting and optimization of the TCO.

- Selection of the CHRYSO®Fibre product best suited to your project specifications.

- Optimized fiber dosage to achieve expected performance levels

- Structural dimensioning of concrete elements.

Automated dosing equipment for exceptional traceability and safety

- Increased accuracy, more flexibility and simplicity compared to manual dosing

- Manual or batch connection

- Extremely reliable and easy to install